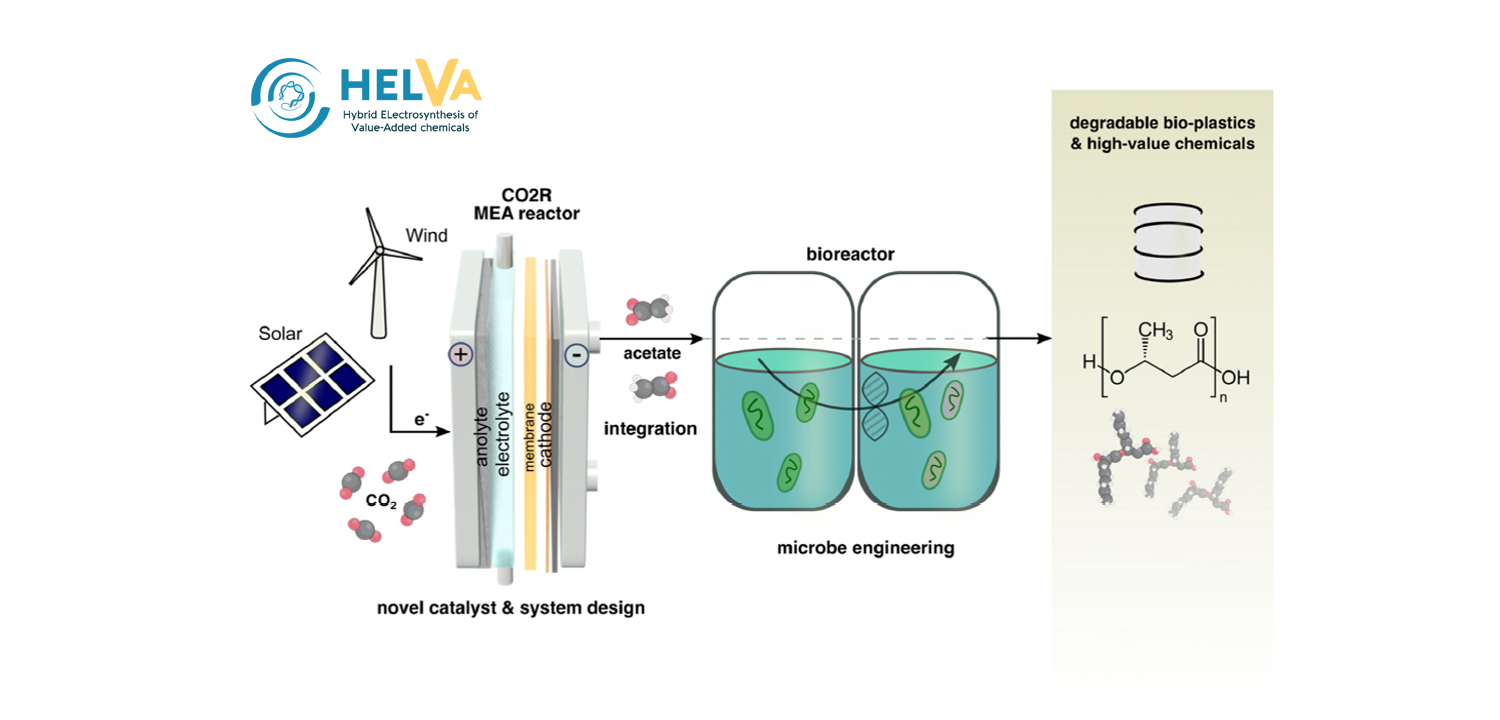

HELVA’s approach involves the integration of two distinct technologies, each addressing a crucial stage in the transformation of CO2 into polyhydroxyalkanoates (PHAs).

CO2 Electrolysis to Acetate

The first phase focuses on advancing the Technology Readiness Level of CO2 electroreduction (CO2R) into acetate. At the project’s initiation, this technology stands at TRL 3 and is anticipated to reach TRL 4 by project completion. HELVA’s strategy involves:

- Innovative Catalyst Design: Development of novel catalysts based on non-critical raw materials, specifically within the family of Cu films doped with transition metals. These catalysts will be complemented by surface polymer coatings.

- Advanced Electrode Integration: Integration of catalysts onto mesostructured gas diffusion electrodes, enhancing the efficiency of the CO2R process.

- Operando Spectroscopy: Utilization of operando spectroscopies, including Raman, infrared, and X-ray-based techniques, to characterize reaction pathways and mechanisms. This information will inform iterative catalyst design.

- Membrane Electrode Assembly (MEA) Reactors: Implementation of catalysts/gas diffusion electrodes into MEA reactors, optimizing the liquid product stream.

Acetate Upgrade into PHAs

The second phase involves upgrading acetate into PHAs. HELVA employs a dual-pronged approach:

- Reactor-Level Design: Engineering bioreactors that consider mass transport, reaction environments, and fermentation routes to efficiently upgrade acetate into PHAs.

- Microbe-Level Optimization: Genetic engineering of microbes to enhance metabolic pathways, accelerating the conversion of acetate species into high-yield PHAs.

Project HELVA was selected in the Joint Transnational Call 2022 of M-ERA.NET 3, which is an EU-funded network of about 49 funding organisations (Horizon 2020 grant agreement No 958174). The project is funded by the Agencia Estatal de Investigación (AEI, Spain); National Science Centre (NCN, Poland); São Paulo Research Foundation (FAPESP, Brazil).

Project HELVA was selected in the Joint Transnational Call 2022 of M-ERA.NET 3, which is an EU-funded network of about 49 funding organisations (Horizon 2020 grant agreement No 958174). The project is funded by the Agencia Estatal de Investigación (AEI, Spain); National Science Centre (NCN, Poland); São Paulo Research Foundation (FAPESP, Brazil).